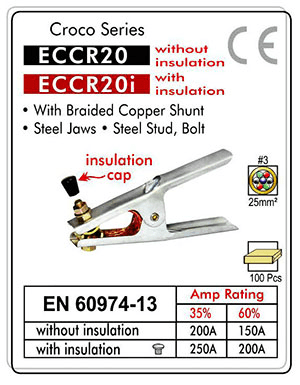

Earth Clamp / Ground Clamp is used to connect the ground cable to the workpiece. It may be connected directly to the work or to the table or fixture upon which the work is positioned. Being a part of the welding circuit, the ground clamp must be capable of carryingthe welding current without overheating due to electrical resistance. The use of a good ground clamp is essential to producing quality welds. Without proper grounding, the circuit voltage fails to produce enough heat for proper welding, and there is the possibility of damage to the welding machine and cables. Three basic methods are used to ground a welding machine. You can fasten the ground cable to the workbench with a C-clamp, attach a spring-loaded clamp directly onto the workpiece, or bolt or tack-weld the end of the ground cable to the welding bench. The third way creates a permanent common ground.

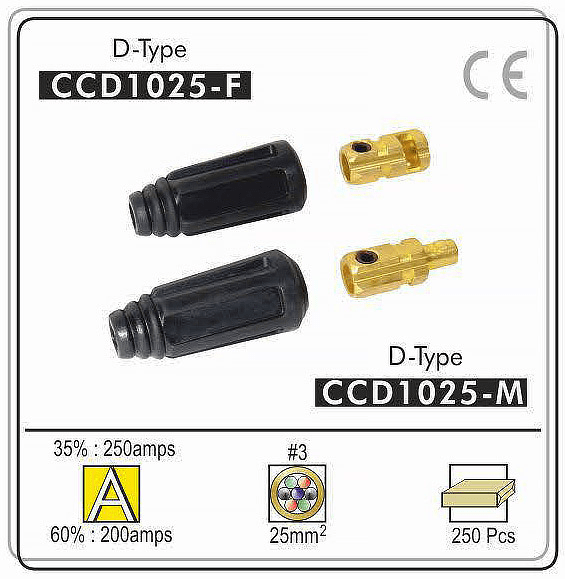

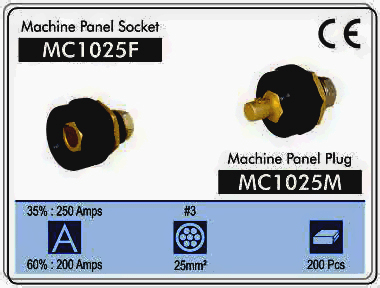

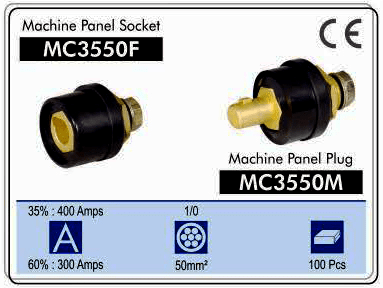

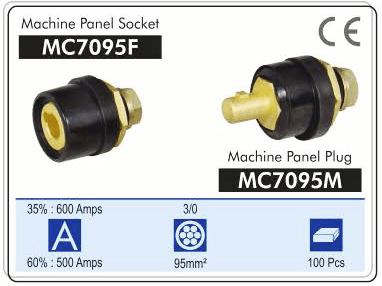

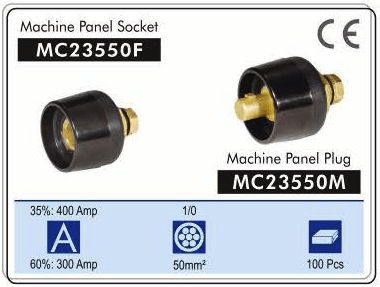

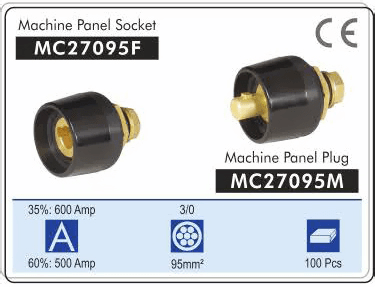

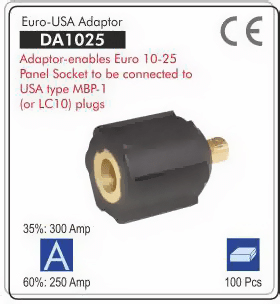

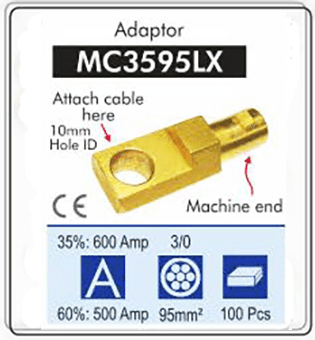

Cable Connectors are used to connect cables to other devices and are specifically designed to maintain the shielding on the cable. A connector is an electro-mechanical device whose purpose is to quickly and easily disconnect or interrupt a circuit path. High-quality connectors offer reliable, long-lasting connections. There are two distinct connector styles male and female. Male connectors have a protruding metal pin in the center, whereas female connectors have a receptacle to receive that pin. Depending on the connector size and frequency, some may be sexless and mounted flush instead of mating. There are several varieties of coaxial cable connector types. Each offers unique benefits based on the end use or application.

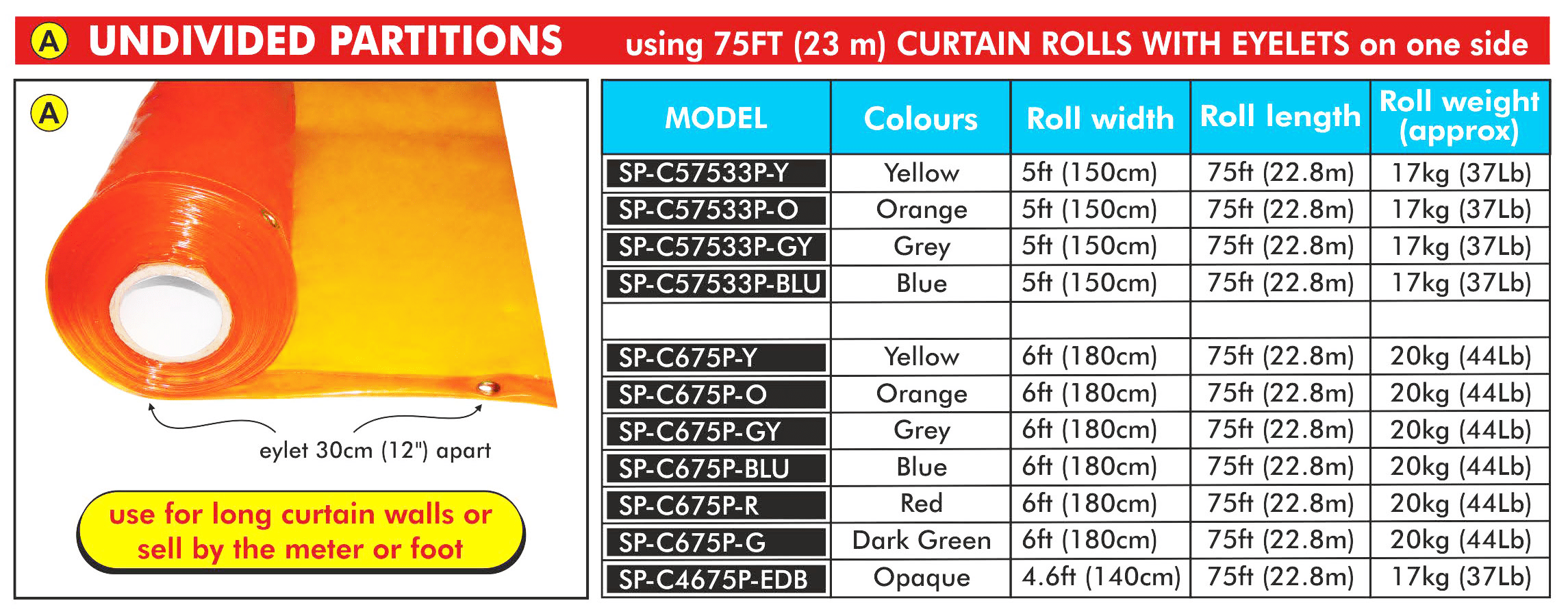

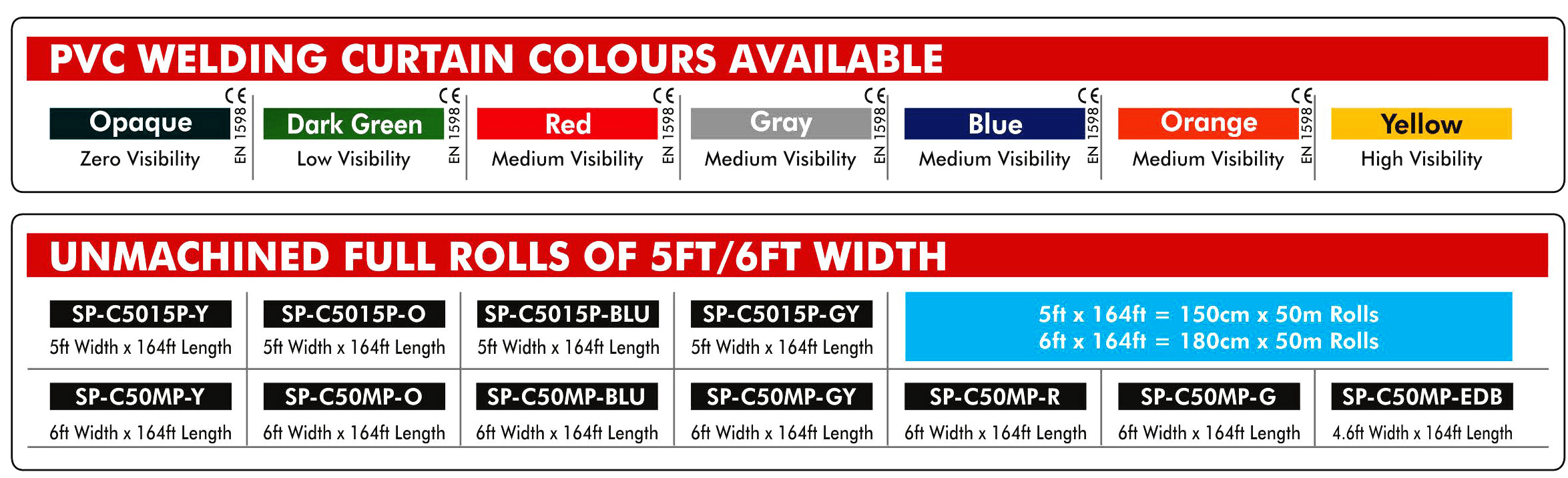

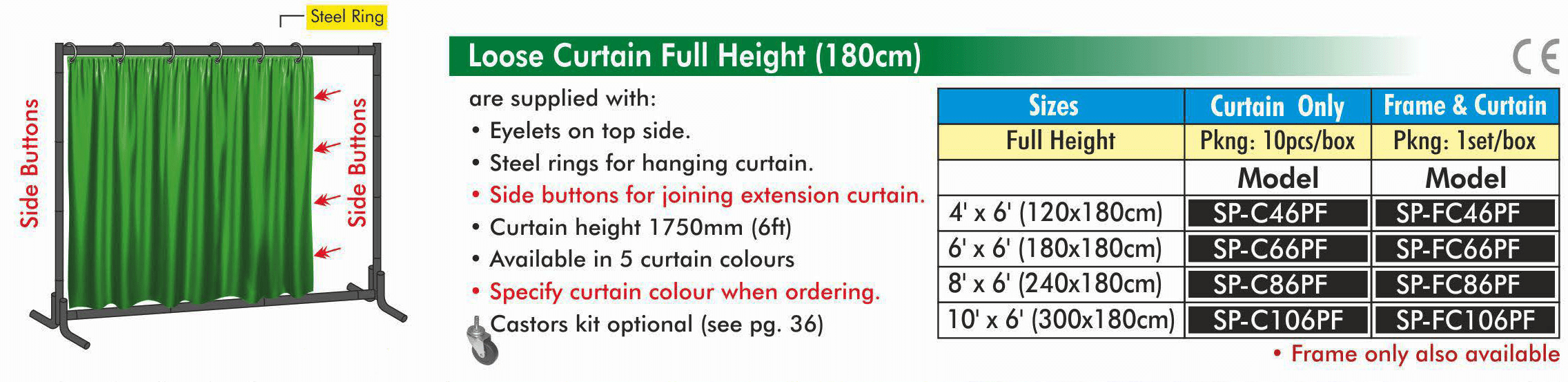

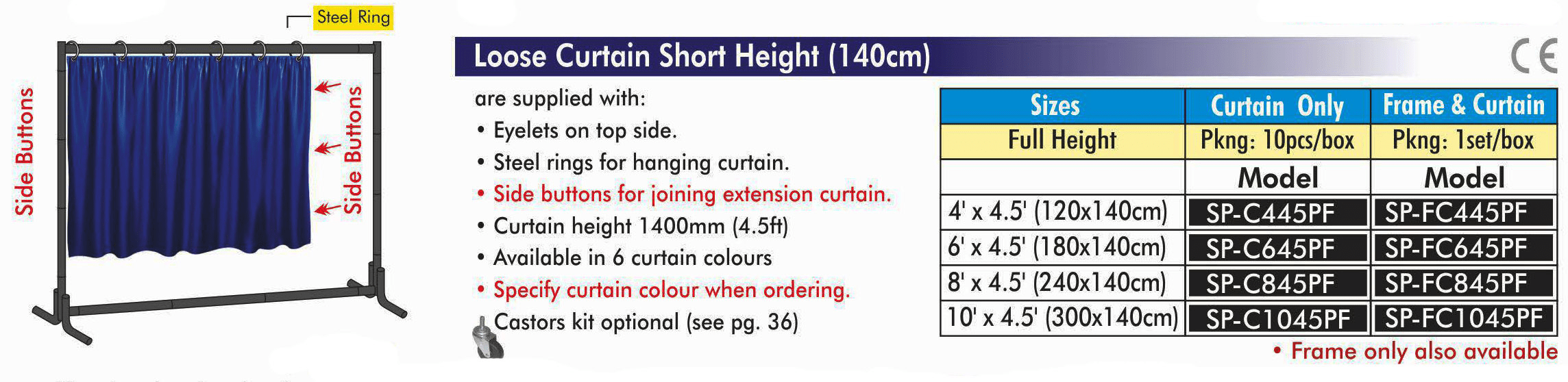

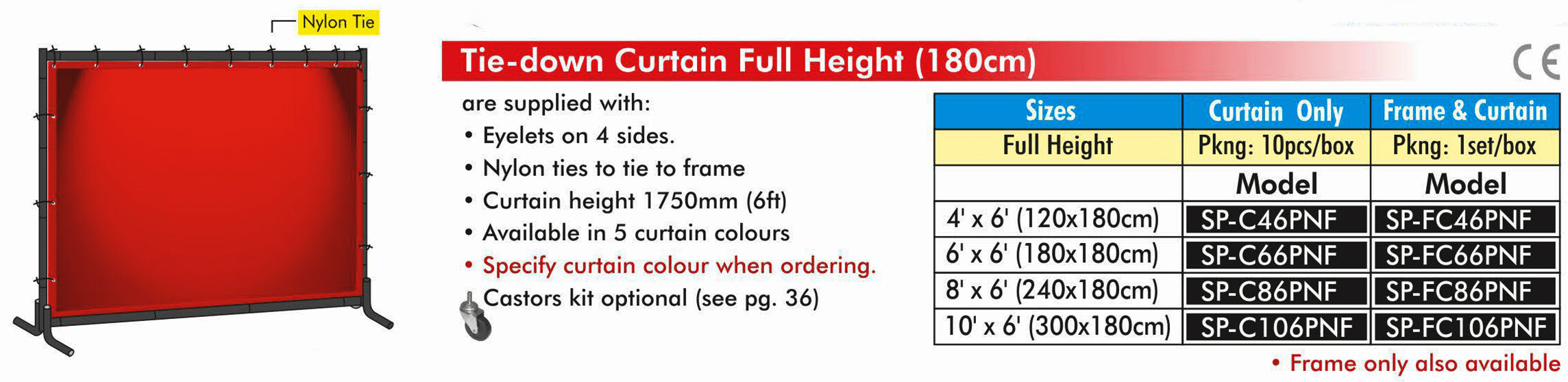

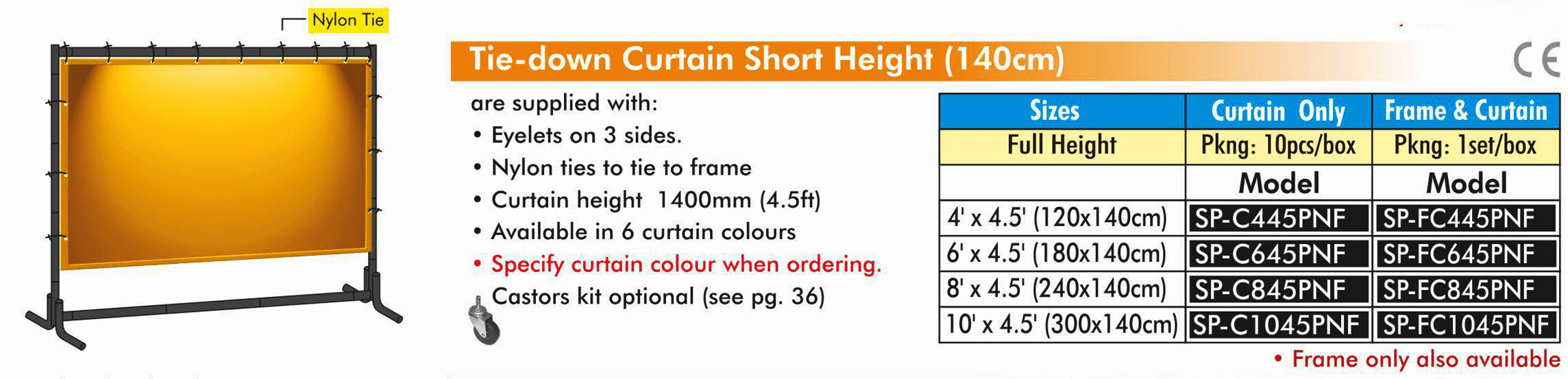

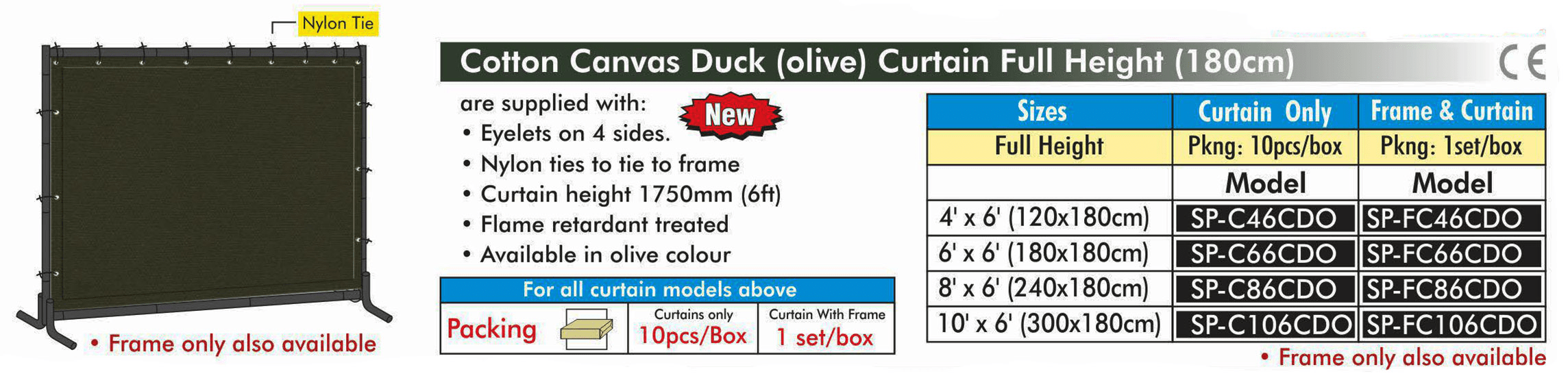

Welding Curtains also means that the size of the welding area is not restricted, as you can cordon an area as big or as small as required. These blankets are also available in a wide range of colors to ensure that they are distinct. During a weld sparks, flames, and molten metal can splash and fall sporadically, so without a welding curtain, anyone near the welding area is at risk of being injured. Creating a well-defined welding area is the first step in ensuring the welder and other employees near to the area are protected. Welding Environment may not be a permanent fixture and the ability to quickly set up and move the welding area could be required. Welding curtains offer this flexibility, as they can be set up easily and customized as required. During a weld, chemicals and fumes that are harmful can be produced. As welding curtains do not create a rigid and closed environment, they allow fumes to flow through. Welding curtains create a barrier between the welding area noise and anyone outside it, reducing the risk of ear damage and overall irritation to employees working nearby.

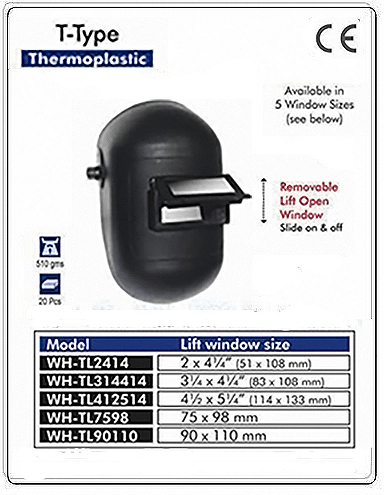

Welding Helmets & Shields are most commonly used with arc welding processes such as shielded metal arc welding, gas tungsten arc welding, and gas metal arc welding. They are necessary to prevent arc eye, a painful condition where the cornea is inflamed. Welding helmets can also prevent retina burns, which can lead to a loss of vision. Both conditions are caused by unprotected exposure to the highly concentrated ultraviolet and infrared rays emitted by the welding arc.[1] Ultraviolet emissions from the welding arc can also damage uncovered skin, causing a sunburn-like condition in a relatively short period of welding. In addition to the radiation, gasses or splashes can also be a hazard to the skin and the eyes

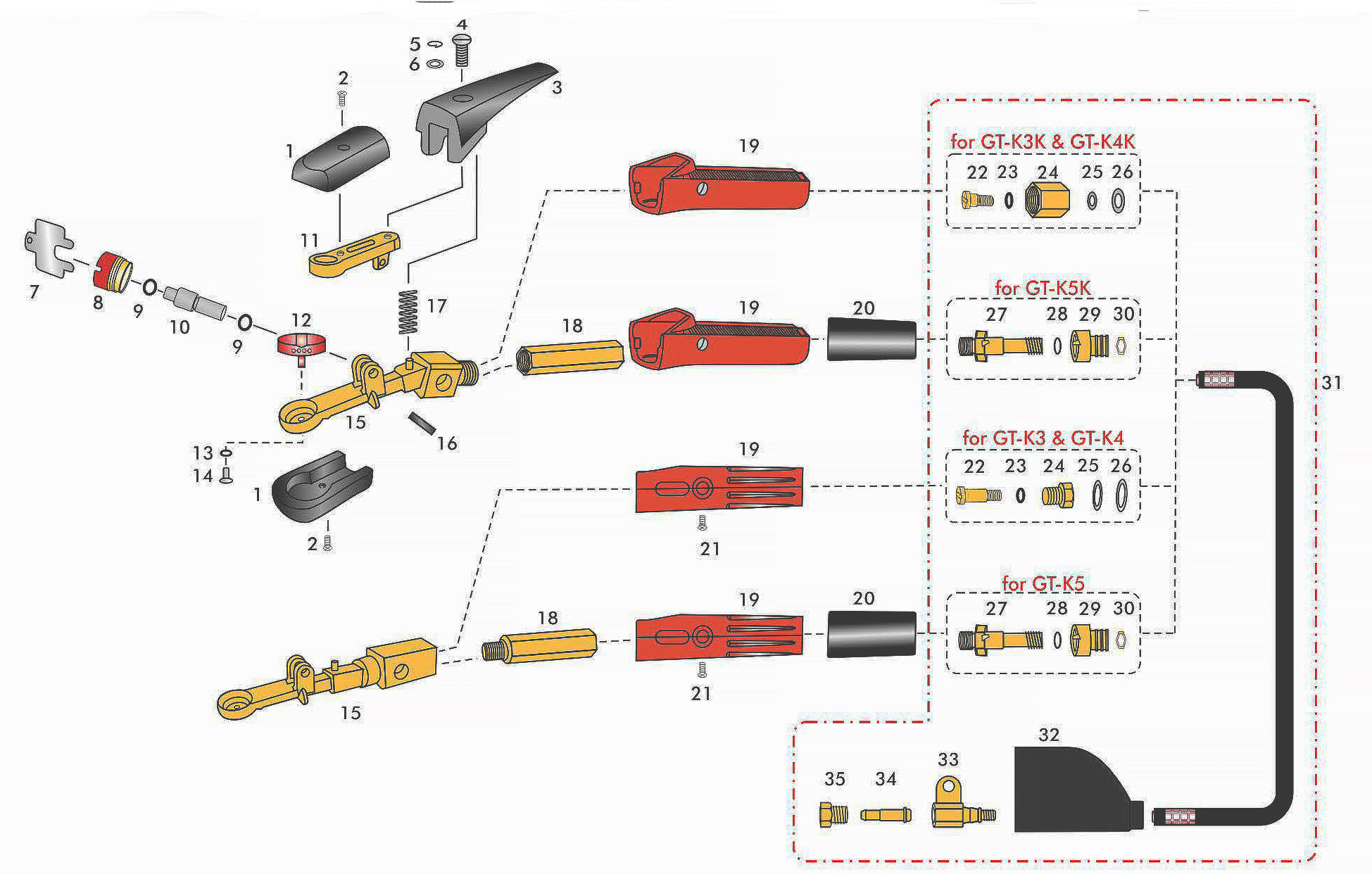

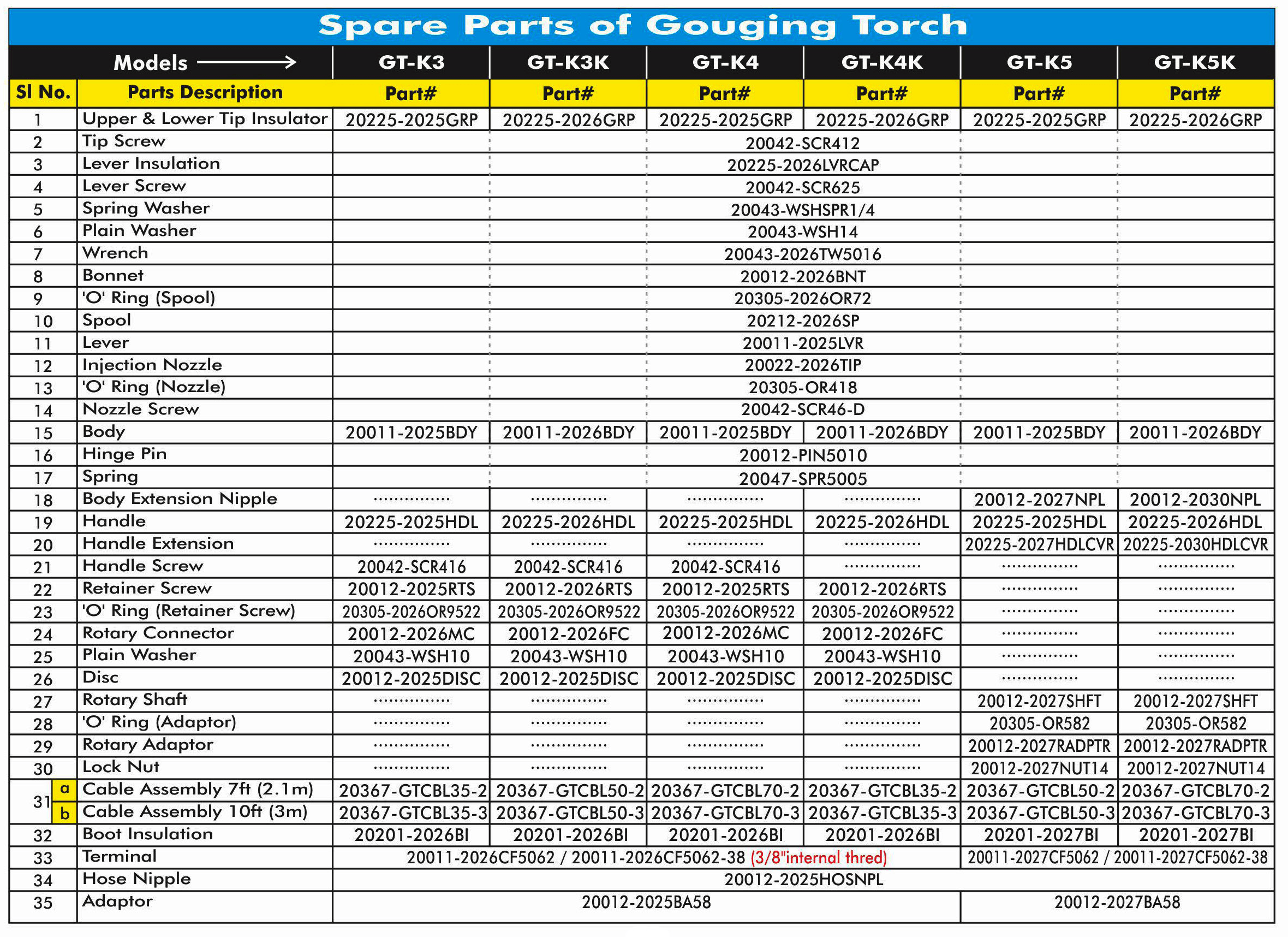

Gouging is a process of removing metal by means of heat generated from a carbon arc. The process uses a carbon/graphite electrode, compressed air and a standard power source. The intense electric arc used between the tip of a carbon electrode and a metal work piece cuts and melts the work piece. The arc is initiated by striking the electrode tip on the surface of the work piece. Then compressed air is used for blowing the molten metal thoroughly from the metal surface. The metal is only cut or gouged along the airflow direction.

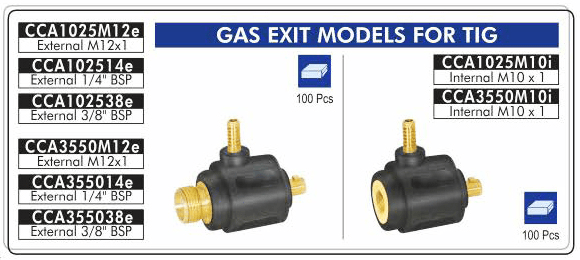

Machine Coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects.[1] Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

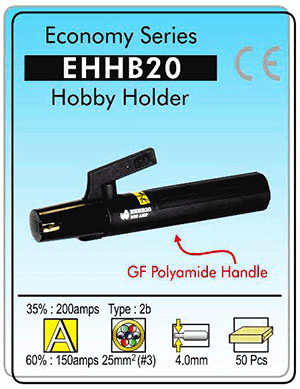

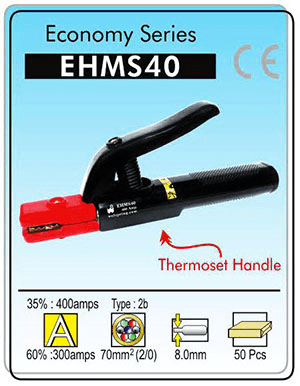

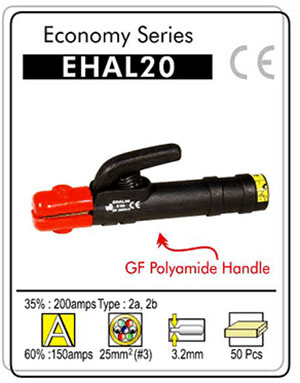

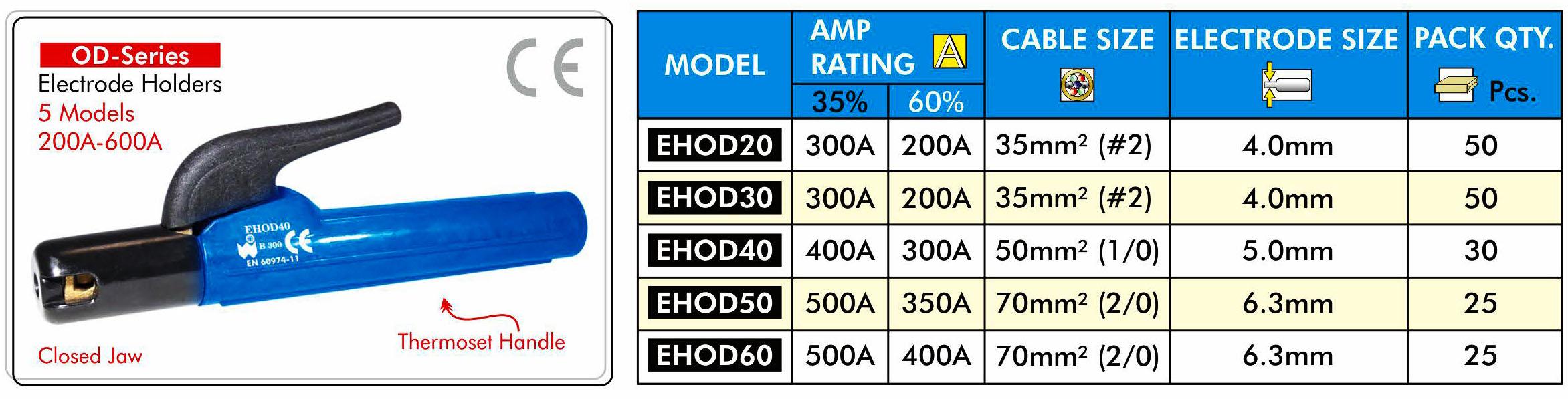

Welding Holder / Electrode Holder is also known as stringer is used as a clamp device to hold an electrode safely in any position. The products that we are offering as a part of this range include all position medium coated rutile electrode and are best suited for producing radiographic quality welds. The electrode holder connects to the welding cable and conducts the welding current to the electrode. The insulated handle is used to guide the electrode over the weld joint and feed the electrode over the weld joint and feed the electrode into the weld puddle as it is consumed. It is designed for use within a specified range of electrode diameters and welding current. You require a larger holder when welding with a machine having a 300-ampere rating than when welding with a 100-ampere machine. If the holder is too small, it will overheat. The design of the electrode holder permits quick and easy electrode exchange.

We are one of the very experienced dealers, with a successfull completion of our 18th year and have been showing an exponential growth in dealing quality products to our clients. We deal and provide our customers the best quality available in the market and consider their satisfaction as our fore most principle of business..