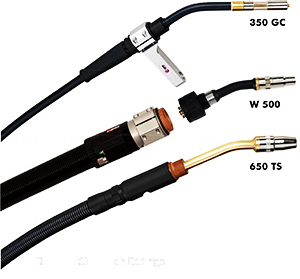

| Model | Type | Duty Cycle | Rating | Wire Size (mm) |

|---|---|---|---|---|

| ABIROB 350 GC | Gas Cooled | 100% | 350 A (CO2) / 300 A (mixed gases) | 0.9 to 1.2 |

| ABIROB A 360 | 360 A (CO2) / 290 A (mixed gases) | 0.8 to 1.4 | ||

| ABIROB A 500 | 500 A (CO2) / 400 A (mixed gases) | 0.8 to 1.6 | ||

| ABIROB W 500 | Liquid cooled | 550 A (CO2 ) / 500 A (mixed gases) | 0.8 to 1.6 | |

| Robo 650 TS | 650 A (CO2 ) / 550 A (mixed gases) | 1.0 to 3.2 |

| Torch Type | FANUC | ABB | MOTOMAN |

|---|---|---|---|

| ABIROB A 500 | iSTM | iSTM | iCAT |

| ABIROB A 360 | |||

| ABIROB W 300 | |||

| ABIROB W 500 | |||

| Robo 350 GC |

| Robot Mount CAT3 (M) cpl | Robot Mount CAT3 (L) cpl |

|---|---|

| Part No. 780.2052 | Part No. 780.2051 |

| Model ADF 615J | |

|---|---|

| Optical Class | 1/1/1/2 |

| Viewing Area | 96 x 40 mm |

| Cartridge Size | 110 x 90 x 9 mm |

| Switching Speed | 1/16,000 s |

| Light State | DIN 3.5 |

| Dark State | DIN 9 - 13 |

| Arc Sensors | 2 |

| Sensitivity Control | Low – High, by infinity dial knob |

| Delay Control Type | 0.1~ 1.0 s. by infinity dial knob |

| Shade control location | External, Variable Shade |

| Grinding Mode | Yes |

| Helmet Material | High impact Resistance Nylon |

| Power Supply | Solar cells, battery replaceable, 1 x AAA Alkaline battery |

| Application range | Stick Welding ,TIG, MIG / MAG; Plasma Cutting & Welding; Grinding; Not for Laser Welding or Oxyacetylene Welding / Cutting |

| Total Weight | 440 gms |

| Approved | GS, Din-Geprüft, CE, CSA Z94.3, ANSI Z87.1 |

| Color | Black |

| Type | Flow Rate | Tank Capacity | Cooling Capacity |

|---|---|---|---|

| CR 1250 | 7.0 lit/min | 6 lit | 1250W |

| 6 litre pack | 192.0265 |

| 20 litre pack | 192.0267 |

| Liquids | |

|---|---|

| 5 litre drum | 192.0052 |

| 20 litre drum | 192.0048 |

| Paste | |

| 300 gms tin | 192.0058 |

| Spray | |

| 400 ml can | 192.0071 |

| Emusion | |

| 5 litre pack | 192.0238 |

| 10 litre pack | 192.0239 |

Gouging Torches- G 3000 & G 4000

| Model | Rating | Duty Cycle | Nom.air pressure | Nom.volume flow | Connection air supply |

|---|---|---|---|---|---|

| G 3000 | Max 600 A | 60% | 7 bar | approx. 0.60 m3 /min. | 3/8” - 18 NPT |

| G 4000 | Max 1000 A | 35% | 7 bar | approx. 0.70 m3 /min | 3/8” - 18 NP |

| Type | Ampere | Pcs | AC / DC Pointed |

|---|---|---|---|

| 4 x 305 mm (5/32” x 12”) | 250 | 50 | AC / DC Pointed |

| 5 x 305 mm (3/16” x 12”) | 300 | AC Pointed | |

| 6 x 305 mm (5/16” x 12”) | 300 | DC Pointed | |

| 6.5 x 305 mm (1/4” x 12”) | 400 | AC/DC Pointed | |

| 8 x 305 mm (5/16” x 12”) | 500 | DC Pointed | |

| 9.5 x 305 mm (3/8” x 12”) | 600 | DC Pointed | |

| 13 x 355 mm (1/2” x 14”) | 900 | AC/DC Pointed |

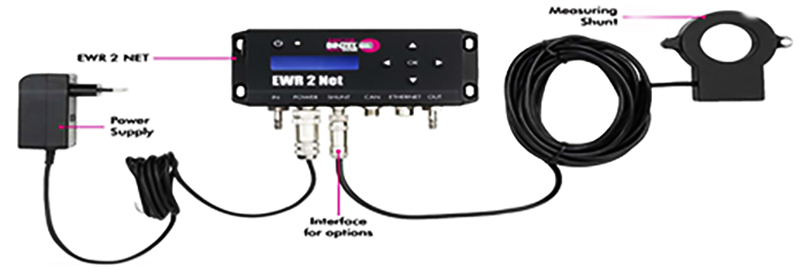

The EWR 2 can do more than just saving gas…

New Range with best ratio of “Performance to Torch Weight” in the entire range of Manual Torches.

Torches with Light-weight “BIKOX® LW” cable assembly, for even better handling and scientifically proven reduced operator fatigue, in all welding positions

| Model | Type | Rating (CO2) | Duty Cycle | Wire Size (mm) |

|---|---|---|---|---|

| MB EVO PRO 15 | Air cooled | 180 A | 60% | 0.8-1.2 |

| MB EVO PRO 25 | 230 A | 0.8 – 1.2 | ||

| MB EVO PRO 24 | 250 A | 0.8 – 1.2 | ||

| MB EVO PRO 36 | 320 A | 0.8 – 1.2 | ||

| MB EVO PRO 501 D | Liquid Cooled | 500 A | 100% | 1.0 – 2.4 |

New Range torch series stands for completely new handling concept. With Ball joint

| Model | Type | Rating (CO2) | Duty Cycle | Wire Size (mm) |

|---|---|---|---|---|

| MB EVO PRO 15 | Air cooled | 180 A | 60% | 0.6-1.0 |

| MB EVO PRO 25 LC | 200 A | 0.8 – 1.2 | ||

| MB EVO PRO 24 VLC | 210 A | 0.8 – 1.2 | ||

| MB EVO 25 | 230 A | 0.8 – 1.2 | ||

| MB EVO 24 LC | 240 A | 0.8-1.2 | ||

| MB EVO 24 | 250 A | 0.8 – 1.2 | ||

| MB EVO 36 | 320 A | 0.8 – 1.2 | ||

| MB EVO 36 HD | 350 A | 0.8 – 1.2 |

Heavy Duty Torches for Flux Core applications.

| Model | Type | Rating (CO2) | Duty Cycle | Wire Size (mm) |

|---|---|---|---|---|

| MB 40 HD | Air cooled | 400 A | 60% | 1.0-2.4 |

| MB 61 GD | 500 A | 1.6-3.2 | ||

| RB 610 D | Liquid Cooled | 650 A | 100% | 0.8 – 1.2 |

Asian style Binzel Torches with small Grip.

| Model | Type | Rating (CO2) | Duty Cycle | Wire Size (mm) |

|---|---|---|---|---|

| AB Grip 20.2 | Air cooled | 200 A | 60% | 0.6-1.0 |

| AB Grip 35.2 | 350 A | 1.0 – 1.6 | ||

| AB Grip 50.1 | 500 A | 1.2-1.6 |

High Efficiency - MIG Welding Torch with facility for extraction of harmful weld fumes at source.

| Model | Type | Rating (CO2) | Duty Cycle | Wire Size (mm) |

|---|---|---|---|---|

| RAB Grip HE 24 | Air cooled | 230 A | 60% | 0.8-1.2 |

| RAB Grip HE 36 | 300 A | 0.8 – 1.2 | ||

| RAB Grip HE 501 D | Water cooled | 500 A | 100% | 1.0-2.4 |

MIG Torches with special extra-long Necks ( up to 600 mm long) and special Contact Tip & Gas Nozzle with specifications as per Models MB 15AK & MB 24KD.

MIG Torches with special extra-long Necks ( up to 600 mm long) and special Contact Tip & Gas Nozzle with specifications as per Models MB 15AK & MB 24KD.

| Torch Description | Options | Type | Rating | Duty Cycle |

|---|---|---|---|---|

| Push-Pull Plus 36 D, 48 V motor, central adaptor GZ-2, 8 Meters | Straight / 45 deg. Bent With or without poti | Gas Cooled | 300 A | 60% |

| Push-Pull Plus 401 D, 48 V motor, central adaptor WZ-2, 8 Meters | Liquid Cooled | 400 A | 100% |

| Model | Type | Rating AC | Rating DC | Duty Cycle | Electrode Dia.(mm) |

|---|---|---|---|---|---|

| SRT - 18 | Liquid Cooled | 320 A | 240 A | 100% | 0.5-4.0 |

| SRT - 26 | Liquid Cooled | 180 A | 130 A | 35% | 0.5-4.0 |

Non-Thoriated Tungsten Electrodes – E3(as per DIN EN ISO 6848) Length = 150 mm

| Diameter | Part No. |

|---|---|

| 1.6 mm | 700.0297.10 |

| 2.0 mm | 700.0298.10 |

| 2.4 mm | 700.0299.10 |

| 3.0 mm | 700.0300.10 |

| 3.2 mm | 700.0301.10 |

| OEM | Torch | System |

|---|---|---|

| HYPERTHERM | PAC110®/PAC120®/PAC125®/PAC140® | MAX20®/MAX40®/MAX42® |

| T80/T80M/T100/T100M | POWERMAX1000®/POWERMAX1250®/POWERMAX1650® | |

| T30v®/T45v® | POWERMAX30®/POWERMAX45® | |

| PAC200T®/PAC200T/E® | HySpeed® HT2000®/MAX200® | |

| PAC170®/PAC600®/PAC620® | HT4000®/HT4001® | |

| HT4400® | HySpeed® HT4400® | |

| HPR130®/HPR260® ms,ss,al | HPR130®/HPR260® | |

| HPR130XD®/HPR260XD® ms.ss.al | HPR130XD®/HPR260XD® | |

| HSD130® ms,ss,al | HySpeed Plasma | |

| KJELLBERG® | PerCut 101®/PerCut 1603D® | HiFocus100®/Hifocus160i® |

| PerCut 370.1®/PerCut 370.2® | HiFocus280®/Hifocus360®/HiFocus440® | |

| PA-S75®/PB-S75®/PB-S76®/PB-S77®/PB-S80® | FineFocus 800®/FineFocus900® | |

| PerCut160®/PerCut170® | HiFocus160i® | |

| ESAB® | PT15®/PT-15XL®/PT19XLS® | |

| PT-600®/PT17A®/PT20AM® | ||

| PT23®/PT24®/PT25®/PT26® | ||

| PT31®/PT31XL®/PT32®/PT34 PT36® |

We are one of the very experienced dealers, with a successfull completion of our 18th year and have been showing an exponential growth in dealing quality products to our clients. We deal and provide our customers the best quality available in the market and consider their satisfaction as our fore most principle of business..